Precision Threaded Products serves aerospace manufacturers, Tier 1 manufacturers and fastener distributors who require fast turnaround on precision fastener orders of 100 to 50,000+ pieces.

We maintain a substantial inventory of certified materials, including high temperature stainless grades 17-4 PH, 15-5 PH, H11, A286, 303 Stainless Steel, Alloy Steel 4140 and 8740, Inconel, Waspaloy, and Titanium.

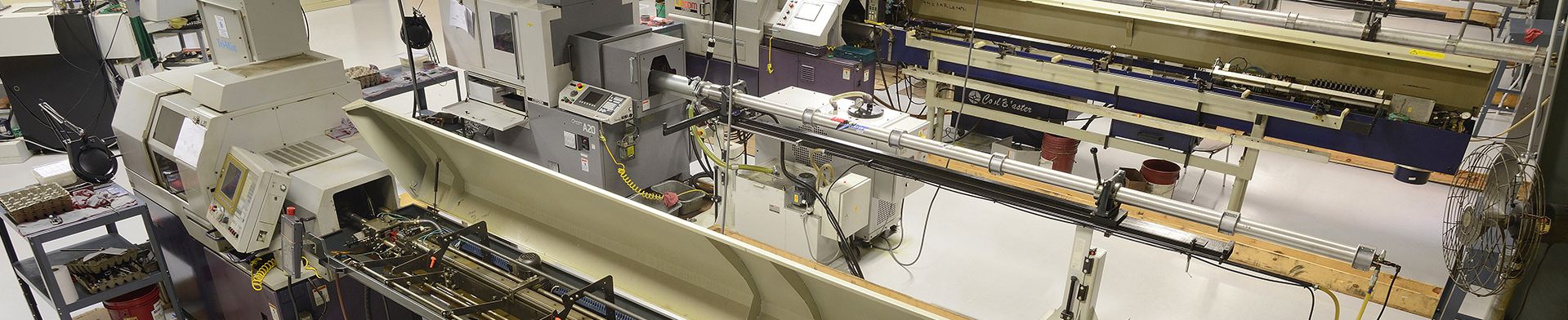

All parts begin with a machined blank from precision bar stock with starting bar diameters of 1/8" to 1 ½" to produce our size range of diameters from 1/16" to 1 ¼" and up to 10" in length.

Secondary operations include:

All components are subject to intensive multi-point inspection protocols during manufacturing. Dimensional laser inspections, photomicrography and chemical inspections are performed on site; we also offer specialized NDT on request.

PTP specializes in custom components manufactured to specific tolerance and material requirements. In addition, we manufacture a wide variety of AN, MS and NAS studs, bolts, pins and screws.

Thread rolling is a type of cold forging that is compatible with any ductile metal. It is the preferred method for producing strong, uniform external threads. For highest quality results, thread rolling is performed on centerless ground blanks.

Rolled threads are often specified due to their superior tensile, shear, and fatigue strength. Where competitive processes produce the threads by removing material, thread rolling displaces the material using hardened steel dies. Dies typically have a Rockwell of 58-63 and dies are specific to each thread size and thread form.

By moving the material into the shape of the thread rather than removing material, the grain structure becomes denser at the critical junctures, especially the root and flank below the pitch diameter. This improves the quality of the thread. Additionally, the burnishing action of the steel dies produces an excellent (better than Ra32) micro-finish. The superior finish improves assembly between external and internal threads and minimizes wear between mating components, extending service life. Roll threaded components from PTP have the important added advantage of a finish that is smoother than ordinary threaded components.

At PTP, studs are manufactured with one, two or three distinctive threads on each; blanks are precision ground to allow pitch diameters as close as ±.0001". Bushings, straight pins and shouldered pins have a standard diameter tolerance of ±.0005".

Our threading department manufactures a wide range of thread sizes and types, up to 1-1/4" in diameter and 4" in thread length. We work on customer-supplied product as well.

To inquire, please send a print and the thread requirements to sales@ptp-inc.com.

PTP is now certified to manufacture HS4773 studs for Boeing and its suppliers.