July, 2025

Precision Threaded Products, manufacturer of the aerospace industry's most advanced fasteners, has been awarded a contract to manufacture studs for the L3Harris RL10 engine. The studs are manufactured from precipitation-hardenable superalloy used in components requiring a combination of high strength and corrosion resistance.

The RL10 was the world’s first liquid hydrogen-fueled rocket engine. It is built by L3Harris and uses cryogenic liquid hydrogen and liquid oxygen propellants.

The RL10 engine has propelled spacecraft to explore every planet in the solar system, including Voyager 1 and 2, the first two spacecraft to reach interstellar space.

Today, multiple RL10 variants are the launch industry’s “workhorses,” powering the upper stages of United Launch Alliance’s Atlas V and Vulcan rockets.

RL10 engines also power NASA’s Space Launch System rocket, which will carry astronauts to deep-space aboard the Orion exploration spacecraft. A single RL10 powered the Interim Cryogenic Propulsion Stage on Artemis I, while four RL10 engines will support the more powerful Exploration Upper Stage that is being developed for future versions of SLS.

May, 2023

PTP announces its certification

as a supplier of HS4773 components to The Boeing Company.

Accredited suppliers are approved to do business with Boeing

Company and its approved suppliers.

The process began with a request from Timken Aerospace Drive Systems (“ADS”) that PTP be added as a supplier of HS4773 studs. Timken requires these ring lock studs for Apache drive system assemblies. Qualifying Precision Threaded Products was shown to improve lead time and reduce cost for the HS4773 standard. PTP is widely recognized as a major producer of ring lock studs to MS and other standards.

The HS4773 product category is a widely used, high-precision ring-locked stud manufactured for use on V-22 Osprey, AH-6 Little Bird, AH-64 Apache, H-47 Chinook, SB Defiant™ and MH-139 helicopters manufactured by Boeing Military Rotorcraft.

July, 2022

PTP has expanded its sales and

service capabilities with the addition of Engineered Components,

Inc., Palmertown, PA to its aerospace sales network.

Engineered Components has, for more than 4 decades, specialized in sales to the aerospace sector, specifically switches, sensors and fluid power systems for OEM and MRO applications. It will provide business development and technical consulting for PTP’s ring and key lock studs and inserts, specialized bolts, screws and shafts, and similar components.

November, 2021

Joe Syryla and Laurie

Kearney greeted customers and prospects at ACM’s annual

exhibition November 10 at Hartford’s Connecticut Convention

Center. ACM comprises one of the largest, most experienced

concentrations of world-class suppliers to the aerospace

industry.

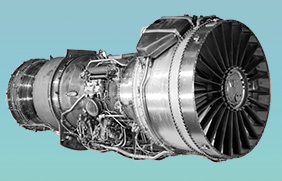

TF33 is the USAF designation for Pratt & Whitney's JT3 commercial engine.

September, 2021

Precision Threaded

Products participated in the development of 16 proposals for the

Tinker Air Force Base Propulsion Directorate relative to the

TF33 Engine. The TF33 boasts decades of performance in military

and civilian service, with more than 1,000 engines currently in

service. The TF33 engine has accumulated more than 72 million

flight hours, most while powering the B-52 bomber, an aircraft

capable of flying at high subsonic speeds at altitudes up to

50,000 feet.

The proposals were part of a US Air Force initiative to rapidly provide manufacturing solutions for TF33 engine parts challenges. Contracts were awarded to PTP and its partners for all 16 proposals. PTP is honored for the opportunity to serve US warfighter efforts through innovative prototyping and manufacturing, and lean practices that streamline lead times.

April, 2021

Precision Threaded Products

has expanded its manufacuring capabilities for precision bolts

to include T-Bolts, a broad category of critical fasteners used

throughout traditonal aerospace and aviation, and in the

rapidly-developing electric aircraft sector.

T-Bolts are widely used to clamp fixtures and tooling, in T-Track clamping systems, in leveling systems, and in engine overhaul operations. Their distinctive head geometry allows both internal and external fixturing. They are generally less costly than hex bolts, the product they often replace. T-bolts can be efficiently manufactured in orders of all sizes and require less machining and secondary processing than other types of aerospace bolts. Learn more

April, 2021

Precision Threaded products

completed its surveillance audit in December, 2020, and was

approved for continued certification to ISO 9001:2015 and AS

9100. As you would expect for an aerospace quality

certification, AS 9100 places a much greater focus on risk

management. This means that PTP documents, evaluates and

mitigates risk in a structured, effective way - allowing us to

ensure the highest level of quality assurance for our customers.

Precision Threaded Products is a PWA LCS, UTAS and GE Approved

Vendor, and is Federal Government / Military Build-to-Print

approved. All PTP products are made in the USA.

March 29, 2021

PTP thanks every member of

our production and administration teams, loyal customers and

vendors for a record sales year! Despite it being a challenging

year, there were many notable high points, including the

addition of a new CNC, a total rebuild of our high-performance

thread rolling equipment and the addition of new thread roll

inspection equipment.

February 24, 2021

Atlas Air Worldwide

Holdings, Inc. has signed an agreement with GE Aviation to

purchase GEnx-2B engines for its four Boeing 747-8 Freighters,

along with a 20-year TrueChoice Overhaul agreement. GEnx-2B

engines are the fastest selling high-thrust engine in GE’s

history, with more than 2,500 sold to date.

GE aviation engines are manufactured using PTP fasteners. PTP is also a leading manufacturer of fasteners for the MRO aerospace market.

February 23, 2021

PTP congratulates its

customer, Timken Company for being named one of the World's Most

Ethical Companies® for the 11th time. Ethisphere Institute,

a leader in defining the standards of ethical business

practices, announced its 2021 honorees today. Ethisphere

assesses a company's culture, environmental and social

practices, ethics and compliance activities, governance,

diversity and initiatives to support a strong value chain to

determine its list of honorees.

Companies from 22 countries earned a spot on the list; Timken is among eight companies honored in the industrial manufacturing category.

January 13, 2021

ALA SpA, a distributor of

PTP fasteners and other precision aircraft components, has been

awarded ISO 14001:2015 certification, a standard that specifies

the requirements for an effective environmental management

system (EMS). The ISO 14001:2015 standard is a voluntary, but

increasingly important certification that provides assurance

that all possible environmental impacts are being assessed,

measured and minimized.

July, 2020

PTP has expanded its professional

staff with the addition of Joseph Syryla as Manufacturing Engineer

and Estimator. The position is broad in scope, and includes several

long-term objectives, including simplifying manufacturing and

estimating processes, developing manufacturing techniques that

reduce scrap, designing broach holders and managing continuous

improvement efforts for several secondary manufacturing operations;

specifically threading, broaching, milling, and stamping. Syryla was

formerly a Manufacturing Engineer and Estimator for Thompson

Aerospace.

U.S. Marine Corps’ AH-1Z Viper

June, 2020

PTP congratulates its long-term

customer, GE Aviation on its award of a five-year, $180 million

contract by the U.S. Naval Air Warfare Center Aircraft Division

to repair and overhaul T700 rotorcraft engines in support of the

U.S. Navy’s MH-60 Seahawk, and the Marine Corps’

AH-1Z Viper and Bell UH-1Y Venom/Huey helicopters.

May, 2020

PTP congratulates its valued

customer, Boeing, on their recent award, by the US Navy, of

$3.1B in cruise missile contracts. Boeing will build the Harpoon

and Standoff Land Attack Missile Expanded Response (“SLAM

ER”) weapon systems in support of Foreign Military Sales.

Boeing last delivered the SLAM ER weapon system in 2008. In October 2019, Boeing began construction on a new 35,000 sq. ft. manufacturing facility to support increased production for the Harpoon and SLAM ER programs.

December, 2019

Pratt & Whitney, a division

of United Technologies Corp. and Juneyao Air celebrated the delivery

of the airline’s first A320neo aircraft powered by Pratt &

Whitney GTF™ engines, a long-time customer of PTP.

Shanghai-based Juneyao Air operates 17 Airbus A320ceo jets, covering

both domestic and international routes.

December, 2019

PTP congratulates its valued

customer, GE Aviation, on receiving an award from the U.S. Army for

the continued production of T700 turboshaft engines in support of

Army, Navy, Air Force, Marines, Coast Guard, Foreign Military Sales

(FMS) and other government agency program requirements through 2024.

The production contract is valued at more than $1B (USD) for as many as 1,700 T700 engines. These engines are manufactured at GE Aviation’s facility in Lynn, Mass.

February, 2019

Precision Threaded Products has

earned accreditation as a supplier of high strength fasteners by

Collins Aerospace (formerly UTC Aerospace Systems-UTAS). Accredited

suppliers are approved to do business with Collins Aerospace and

other UTAS-approved suppliers.

In addition to UTAS certification, Precision Threaded Products PTP has a robust internal Quality Management System (QMS). It maintains AS9100/ISO 9001:2015 Rev. D certification, is GE approved, and holds a PWA LCS. It is included on DLA’s QSLM for Class 3 Threaded Fasteners. PTP is Federal Government / Military Build-to-Print approved.

April, 2018

PTP congratulates its valued

customer, GE Aviation, on its recognition by Sikorsky for

exceptional supplier performance.

GE Aviation achieved Rotary and Mission Systems (RMS) Elite Supplier status after demonstrating exceptional quality, delivery and customer support performance related to Sikorsky’s UH-60 Black Hawk aircraft.

On March 15, GE Aviation completed its first flight test of the world’s largest jet engine, the GE9X. GE is building the GE9X for Boeing’s new 777x long-haul airplane. The GE9X engine lifted off March 14, under the wing of GE Aviation's Boeing 747 flying test-bed in Victorville, California.

PTP is now certified to manufacture HS4773 studs for Boeing and its suppliers.